Link Love – The Beads or Chandelier Quilt

Free patterns are always fun, aren’t they? Well, today I have a delightful pattern recommendation to pass along to you: a pretty, on-point Beads quilt pattern by Donna Jordan from Jordan Fabrics. There’s even a video to go with the pattern! Scroll down the page to see the video. Here’s what inspired this project – […]

Read More

Testing My Quilt Marking Tools

What should I use to mark my quilt? This seems to be one of the most commonly asked questions in the quilting community – and sometimes, one of the most controversial. The short answer is whatever gives you results that please you. But who wants to spend a lot of money on tools that may […]

Read More

Making a Rope Bowl or Basket

There’s no single “right” way to make a rope bowl. In fact, if you search for tutorials online, you’ll be inundated with a wide variety of approaches. Over the years, I’ve tried quite a few different methods; the tips and techniques I’m sharing today are some of my favorites. For this project, I started with […]

Read More

Stay Stitching is Your Friend!

I’m thrilled that so many of you are enjoying my latest FREEBIE! But I’m finding there is one line in the printable Fabric to Finished Quilt checklist that some of you are wondering about. What is stay stitching? Why is it recommended? In this specific example, stay stitching is running a single line of stitches around the entire […]

Read More

Easy & Elegant Echo Quilting

Machine quilting doesn’t need to be fussy, difficult, or complicated to be effective (Although over-the-top quilting can certainly be gorgeous!) One of my favorite techniques that is also super-easy and beginner-friendly is echo quilting. Echo quilting is simply choosing a seam in a pieced quilt or the edge of an appliquéd shape and stitching parallel […]

Read More

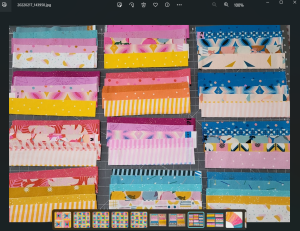

Evaluating Relative Values

I’m getting ready to teach my Color Gets the Credit but Value does the Work class at the AQS show in Grand Rapids, Michigan, and I thought it might be helpful to post a quick overview of the methods I recommend for evaluating the relative value of the fabrics in your quilt or other project. […]

Read More

Fun with Fussy-Cutting

I’ve been working on a new bed quilt lately; and as I’ve been cutting my fabric, I’m starting to accumulate quite a pile of new scraps. I started setting some of the scraps to one side. I had an idea… Fussy-cutting is a fun way to feature a specific design or motif in a fabric […]

Read More

FREE PROJECT – Fast & Fun Folded Fabric Stars

These scrap-busting stars make great holiday ornaments or decorations, and are easy enough that kids can enjoy making them, too. 😊 What You’ll Need: 3 strips of fabric for each star I used 3” x 10” strips for the larger stars and 2” x 7” strips for the smaller star. You can use 3 strips […]

Read More

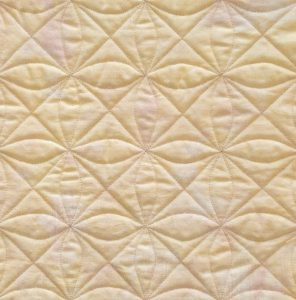

Revisiting Continuous Curve Machine Quilting

Back in June, I shared a step-by-step tutorial for Continuous Curve Machine Quilting with a Walking Foot. This quilting pattern has been a favorite of mine since I first learned it almost 30 years ago. The version I shared was (and is) a fantastic beginner-friendly starting point, but I thought you might be ready for […]

Read More

Choosing Thread for Machine Quilting – Let’s have some fun!

How do YOU decide what thread to use when you machine quilt? Do you have a go-to favorite? Have you ever played with any other options? My go-to thread is 50wt. Aurifil cotton – the same thread that I use for piecing my quilts. It’s strong, colorfast, easy to work with, reliable, and has just […]

Read More