I should have known, first thing in the morning when my 30 ounce environmentally friendly metal tumbler full of organic pu-erh tea and coconut cream completely upended all over a four foot radius of bedding, pillows, books, magazines, bedside rug and slippers that it wasn’t going to be an auspicious day for precision work.

But I’m an essentially optimistic person, so I decided to proceed with my plans to machine quilt my invisible machine appliqué teaching sample anyway.

What followed what a series of unfortunate events punctuated by the occasional expression of shock and consternation.

It wasn’t just the tea that should have tipped me off that the stars were not in alignment that day.

The first step was to assemble my quilt “sandwich” of quilt top, batting, and backing. I soon discovered that the supposedly fusible batting I had specifically purchased for this project wasn’t fusible after all. So no biggie, I thought, we can improvise.

I found a leftover piece of Thermolam to use in place of the batting. (I often use this for items like placemats or table runners, as it is nice and flat. I also like it for small sample pieces that have to be packed and unpacked as the needled fleece is less likely to hold creases than cotton batting.)

Unfortunately, it turned out to be leftover because it, too, was the nonfusible kind instead of the Thermolam Plus that I normally prefer. Oh well.

I turned to my old reliable standby, 505 spray. But my can of 505 proved to have nothing but sputter left in it. Then I found a can of Dritz 403 Spray Adhesive, which I’ve never used before, and can’t remember when, where or why I purchased it. I managed to spray myself and half my work table before getting the layers safely bonded. (And no, I’ve never made such a mess when spray-basting a quilt before, and it wasn’t the fault of the product – I was just having an incredibly “off” day…)

I set up my machine with .004 monofilament thread and Bottom Line in the bobbin. Somehow I forgot to put in a new needle… more on this later.

I took the quilt to my machine to do the straight line “in the ditch” quilting with my walking foot. Midway through the process (I was listening to an audio book, so my attention was admittedly divided), I realized that the fabric was shearing and my straight lines and perfect corners had become misaligned. It turns out that I had accidentally grabbed my old walking foot, instead of my new walking foot, and the fabric was not feeding properly as I stitched away. (Yes, a walking foot can wear out over time.)

I reverse-sewed (AKA ripped out) the most egregious portions of the stitching, but decided that there was no way I was going to rip out everything – it would have taken too long!

So I pressed on. Not, perhaps, the wisest move; but as I mentioned before, I tend to be an optimist.

Quilting in the border complete (albeit still a bit more wonky than I initially realized), I moved on to stitching around each of the appliquéd pieces. That actually went OK.

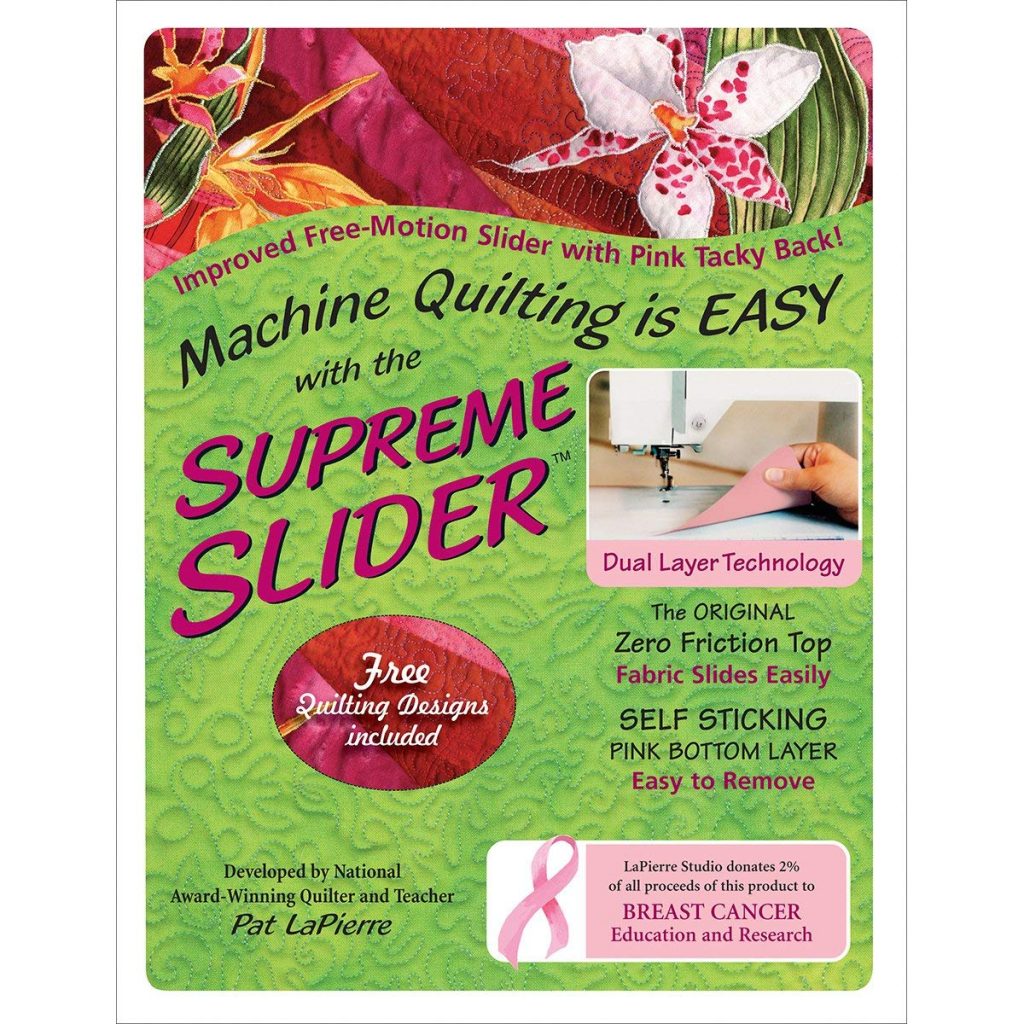

Then it was time for free-motion quilting in the negative space around the appliqué. I noticed that the extension table wasn’t perfectly even with my sewing machine, so I pulled out the Supreme Slider that I’ve had for at least a decade, but never used. This turned out to be one of my best ideas of the day – it worked beautifully!

So I’m tootling along with my Machingers on, sticking with stippling, as I wanted the emphasis to be on the appliqué rather than the quilting, and all of a sudden, the needle broke. Now this has happened to me a couple of times over the years, but what has never happened before was that the broken, jagged metal portion of the needle still in the machine continued to stab the quilt repeatedly, creating a jagged hole. Apparently, instead of hitting the “stop” button, I had hit the “reverse” button…

Fortunately, I was able to carefully poke the pulled and broken threads back into the surface of the quilt with a large chenille needle and use Fray Block to stabilize the traumatized area. (Note: In my experience, Fray Block is an excellent product that dries clear and soft without discoloration over time, but ONLY if you use it in the recommended VERY SMALL amount.)

After the area was dry, I continued free-motion quilting with a Microtex Sharp needle, size 70.

Getting my groove on… Notice how I only move 1 hand at a time, keeping at least 1 hand in direct contact with the quilt at all times.

Done!

I trimmed off the excess batting and backing.

The borders are still a little irregular (because of the distortion from the non-working walking foot), but I plan to wash and block the quilt after it is bound, so that should help.

I may also go back in and echo-quilt just inside the flower pot and perhaps the flowers, too.

But I think I’m going to take a break for a bit…

PS: Before I forget again – for my friends from my class at the Knapp’s Corner store – here is the link for the freezer paper I ran through my printer and gave out in class: